MRI Design Drivers

Dennis Posen, AIA

Magnetic resonance imaging, or MRIs, use magnetic fields and radio waves to generate soft-tissue images and require a strong and uniform magnetic field. Typical MRI field strength varies from (1.0 to 7.0), 1.5 to 3.0 Tesla. An MRI suite can be an expensive undertaking – costing between $3 to $5 million when all expenses are tallied, including the cost of the equipment itself.

Because of this investment, combined with the complexity of MRI systems and required construction protocols, these suites can be challenging to design. Owners should be aware of the following considerations when designing an MRI suite.

Understand Components of an MRI Suite

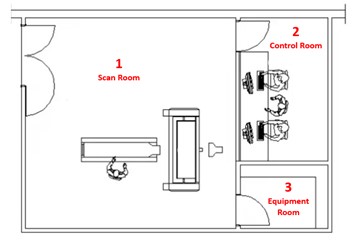

An MRI suite is comprised of three rooms:

1. Scan Room: This room is where the magnet and the table are located and where patients are scanned.

2. Equipment Room: This space holds gradient cabinets, compressors, and other electronics that connect to the magnet.

3. Control Room: The technologist works from this room during the scan.

For outpatient MRI suites, a changing area is also included for patients and contributes to an enhanced patient experience.

Location. Location. Location.

Select your MRI suite location carefully, including areas above and below the MRI location and on the exterior of the building as a number of things including power lines, traffic patterns, moving metal objects, elevators and other exterior elements can significantly impact MRI performance. The weight of the machine may also require additional structural support and additional HVAC considerations. It’s important to research all of these issues BEFORE committing to a specific location for your MRI suite.

Patient Safety Is Key

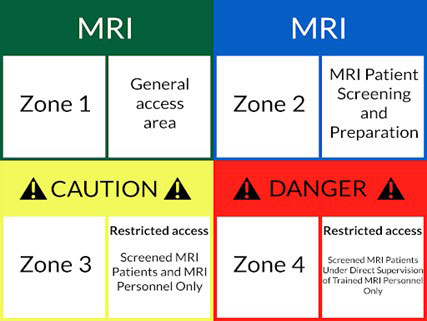

Because the magnetic field of the MRI is so strong, it can attract – at high speeds – any item made of ferrous (steel/iron) material including wheelchairs and oxygen tanks creating a “projectile effect” that can cause serious injuries to patients or staff. With safety in mind, the American College of Radiology has developed a four-zone plan for MRI facilities that establishes increasingly restricted occupancy zones as the patient moves from the unregulated public zone outside of the MRI suite to the most highly restricted zone of the Scan Room.

Impact of Size and Weight of MRI Equipment

MRI equipment is heavy. A 1.5T scanner can weigh as much as 10,000 pounds and a 3.0T scanner tips the scale at over 17,000 pounds. And this weight is concentrated in a very small footprint creating structural support concerns. In addition, Control Room equipment can weigh an additional 2,000 to 3,000 pounds. For this reason, MRI suites are typically located on ground floors. However, with appropriate structural engineering, MRIs can be located anywhere in a facility.

It is important to review the path of travel for bringing the MRI equipment into the building. Remember to verify the dimensions of all corridors in the travel path and investigate the potential impact of handrails, lighting and equipment fixtures, ceiling cameras, and signage. Measure the length of the bore to make sure corner turns can be accommodated. Because of its large width and height, MRI equipment cannot be brought in through ordinary doors. Measure the height of your proposed MRI magnet. Some magnets feature tilt frames, allowing them to clear a normal 7’-0” door. Newer magnets are taller and may require increasing existing door frame heights. Most MRIs require an 8-foot-wide by 8-foot-high zone to move the magnet through the building.

A capacity check of the floor along the path of travel should be conducted to determine if potential reinforcement of the floor is required. It is important to review elevator capacities as well if the MRI is being placed on upper floors. These issues require the involvement of a structural engineer, specialized medical equipment rigger, and the elevator maintenance company.

Shielding Requirements

There are multiple shielding requirements for MRI spaces to ensure accurate imaging and patient and staff safety. The walls of the magnet room must be constructed in layers to perform several independent functions: radio-frequency (RF) shielding to prevent electromagnetic noise from entering or leaving the room, magnetic shielding to confine the fringe field, and acoustic shielding to restrict noise transmission to the control room and beyond.

- Radio Frequency Shielding

MRI machines are significantly impacted by radio frequencies (RF) from a variety of common electronic devices, such as transformers, motors, and computers. The RF shield must line all surfaces in the room, including the ceiling and floor in order to protect the MRI system from exterior radio frequencies to ensure clarity of scan. Thin layers of either copper or galvanized steel are attached to plywood sheets. To accommodate the shielding, floors should be recessed 1.5 inches in order to create a smooth transition at the door. The footprint for the RF shield is determined during the design process and should be confirmed by a qualified RF shield contractor to safely accommodate details that must penetrate the shield, like duct work, conduits, plumbing, and electrical outlets.

- Magnetic Shielding

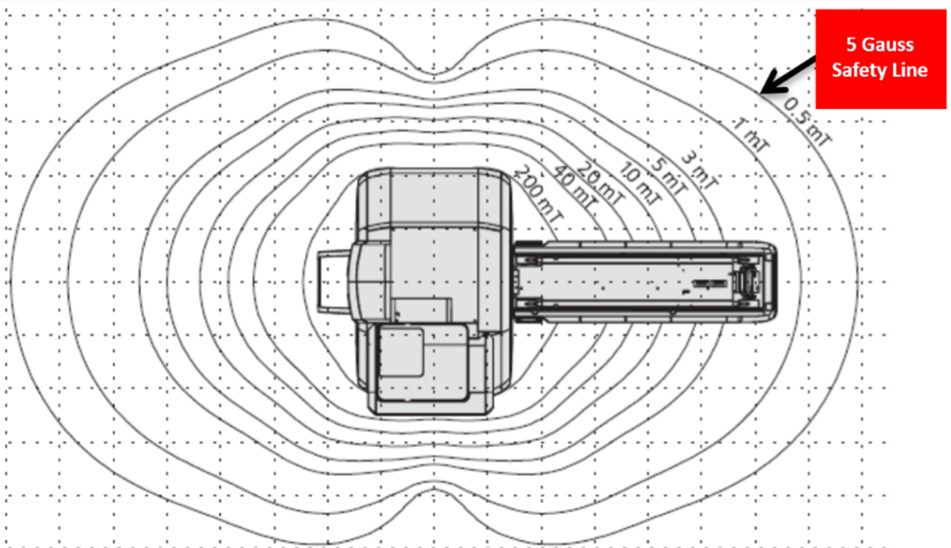

In addition to being sensitive to radio frequencies, MRI machines produce high magnetic fields that can interfere with other instruments, creating significant safety and operational impacts. These magnetic fields can pass through walls in every direction impacting not only adjacent rooms, but areas above or below the MRI room depending on the strength of the magnetic field. MRI magnetic field strength is measured by gauss units named after mathematician Carl F. Gauss. The magnet field produced by earth is 0.5 gauss. The magnet field produced by the magnet in a 1.5T MRI machine is 15,000 gauss, meaning the magnet in a 1.5T scanner is 30,000 times stronger than that produced by the earth. And as outlined above in the patient safety section, bringing ferrous materials within a 5 gauss limit poses severe safety risks. When designing an MRI suite, remember that the 5 gauss line can extend beyond the room into adjacent areas and public spaces.

RF shielding has no effect on the magnet fields produced by an MRI magnet, so MRI suites require magnetic shielding as well. To provide magnetic shielding, thin sheets of galvanized steel are installed separately from the RF-shielded enclosure to ensure the magnetic field is contained. A physicist, hired by the hospital, architect or MRI vendor will determine the location and thickness of the plates. These plates are heavy, so remember to have the steel plates reviewed by a structural engineer to verify that the building structure can support these loads. A specialty consultant provides the design and installation of the magnetic shielding.

Vibration

MRI scanners must be installed in a low vibration environment to ensure good imaging. Scanner exposure to high levels of low-frequency vibration negatively impacts image quality and can contribute to inaccurate diagnoses. Common vibration culprits are mechanical equipment, vehicular traffic, and foot traffic, especially if the MRI suite is located on an elevated floor. Be aware that vibrations can move through the structure over multiple floors, so the source of the vibration may not be adjacent to the MRI. While advanced MRI technology has made magnets lighter and faster, they are also more susceptible to vibrations. Due to their size and weight, many MRI suites are located on the first floor or grade level. Consider installing isolation joints in the floor slab to mitigate floor vibrations.

Acoustics

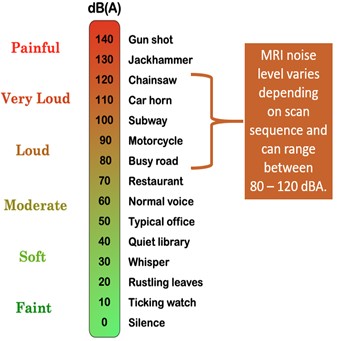

MRI scanners are capable of producing sound levels in excess of 110 dBA which can travel and be disruptive to adjacent occupants in the building. Carefully select materials and pay particular attention to construction details to assist with sound absorption and avoid locating patient areas and meeting spaces directly adjacent to MRI suites. Have the manufacturer confirm decibel levels for the specific equipment. Mitigation strategies should bring noise ratings to 45 dBA. Consider engaging an acoustic and vibration consultant to provide vibration and sound dampening recommendations.

Commissioning

Consider having the RF and electromagnetic shields, reviewed by an independent third-party commissioning agent. This will confirm that everything has been installed correctly and will help ensure that no artifacts appear on the scans.

Engineering Upgrades

MRI suites need specific engineering considerations due to the specialized requirements for heating and cooling, electrical loads, and fire protection. Early in the design process, ask the equipment manufacturer to provide information regarding heat loads, humidity ranges and chilled water requirements, all which will impact the design. Also remember to review life safety information as each manufacturer has slightly different requirements and allowances.

If renovating, remember to review the existing fire sprinkler system as the system will need to be altered in and above the MRI room. The sprinkler system needs to be constructed of non-ferrous materials such as copper, brass, or stainless steel. It is important to evaluate which upgrades may be required and take these into account in deciding the location of an MRI suite.

An MRI suite can be a significant investment for a health system due to the cost of the equipment, but it is also one of the highest potential areas of benefit to patients in a healthcare building. By following the recommendations outlined above, your MRI suite will ensure the safety of both patients and staff.